Tenac™

Polyacetal Resin

Our Polyacetal (POM) product category includes a diverse range of Tenac™ copolymer and homopolymer compounds. While homopolymers have greater versatility, allowing them to work with different mechanical and structural parts, Tenac™ copolymers offer an advantage of chemical resistance and improved stability.

POM Material Manufacturers Provide Plastic Solutions for Improved Stability

If you're looking for a highly stable thermoplastic, our polyoxymethylene (POM) products could be the plastic solution you need. Asahi Kasei Plastics North America (APNA), Inc. offers Tenac C™ copolymer acetal resin materials, or POM, and Tenac™ homopolymer acetal resins. These high-performing materials possess ease of molding throughout the range of conditions generally employed for polyacetal resins, as well as balanced combinations of the properties required for engineering plastics.

TENAC

Window Assembly

Benefit: Creep

TENAC

Inner Door Handle

Benefit: Metallic Aesthetics

TENAC

Seat Belt Button

Benefit: Low Emissions

Properties of Acetal Copolymer & Homopolymers

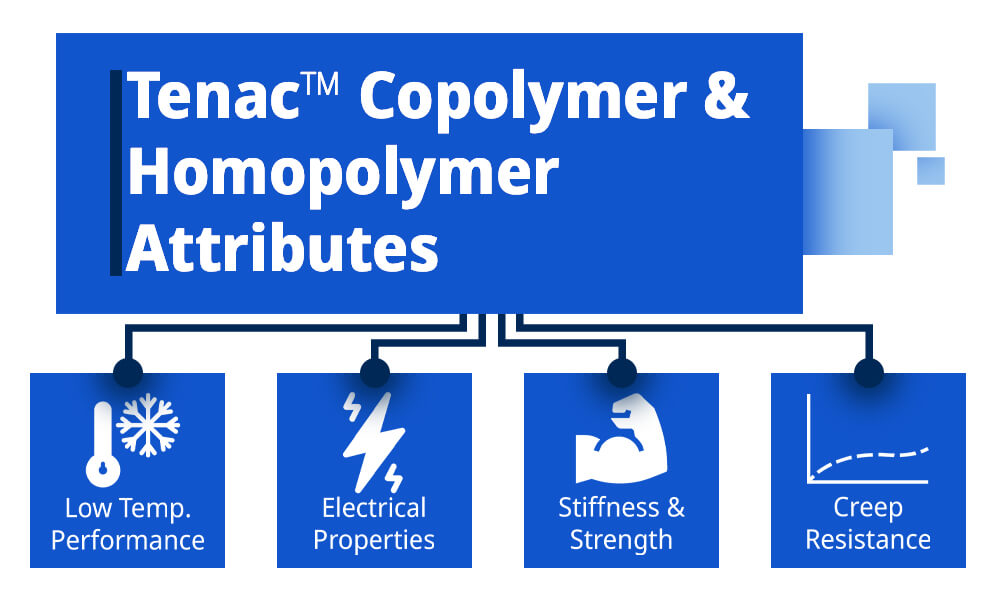

Tenac™ copolymer and homopolymer compounds feature the following attributes:

Acetal Copolymer Applications

Our line of Tenac™ polyoxymethylene products offers a thermoplastic with excellent stability, commonly referred to as polyacetal (POM). Tenac™ products are common in commercial applications that require high durability, superior aesthetics, low friction and wear resistance.

What is POM plastic (polyoxymethylene)?

Copolymer acetal plastic also called polyoxymethylene (POM) and polyacetal (acetal), is a semicrystalline, general-purpose engineered thermoplastic. Acetal is commonly used for parts that need to have adequate dimensional stability, the term for a plastic part's ability to maintain its original dimensions when exposed to humidity and temperature changes. Acetal copolymer is also employed in high-performance engineering components.

Widely used in the automotive and consumer electronics industries, acetal copolymer resin can be found in a wide variety of products:

Advantages of Acetal Copolymer Resin

Acetal copolymer is revered for its toughness, rigidity and high strength. It possesses exceptional friction and wear properties that can be improved by compounding with additives.

Copolymer material is easy to machine-like acetal homopolymer resin. However, acetal copolymer resin exhibits better resistance to inorganic and organic acids and solvents.

Choose APNA for Your Polyoxymethylene (POM) Needs

If you're interested in looking more closely at our Tenac™ product line, feel free to browse our technical data sheets or reach out to us online.