LEONA™ Key Features

Heat Resistance

LEONA™ has a high melting point (265°C) in general-purpose engineering plastics and boasts excellent heat resistance.

Electrical Insulation

LEONA™ features excellent electrical insulation and tracking resistance. These properties are derived from the absence of benzene rings in the molecular structure.

Mechanical Properties

LEONA™ features excellent strength and rigidity. These properties are derived from the molecular structure of PA66 resins, which feature tightly interwoven polymer chains with hydrogen bonds acting between molecules.

High Toughness & Impact Resistance

LEONA™ has high toughness and impact resistance derived from the molecular structure of PA66 resins, which allows them to exhibit water-absorption-induced plasticity.

Resistance to Oil & Organic Solvents

LEONA™ features excellent resistance to non-acid chemicals, organic solvents, lubricant oils, and similar substances

Optional Fillers for Strength Reinforcement

LEONA™ has high intermolecular cohesion and does not become brittle even when compounded with fillers.

LEONA™ Key Features

Heat Resistance

LEONA™ has a high melting point (265°C) in general-purpose engineering plastics and boasts excellent heat resistance.

Electrical Insulation

LEONA™ features excellent electrical insulation and tracking resistance. These properties are derived from the absence of benzene rings in the molecular structure.

Mechanical Properties

LEONA™ features excellent strength and rigidity. These properties are derived from the molecular structure of PA66 resins, which feature tightly interwoven polymer chains with hydrogen bonds acting between molecules.

High Toughness & Impact Resistance

LEONA™ has high toughness and impact resistance derived from the molecular structure of PA66 resins, which allows them to exhibit water-absorption-induced plasticity.

Resistance to Oil & Organic Solvents

LEONA™ features excellent resistance to non-acid chemicals, organic solvents, lubricant oils, and similar substances.

Optional Fillers for Strength Reinforcement

LEONA™ has high intermolecular cohesion and does not become brittle even when compounded with fillers.

Asahi Kasei is proud to offer an extensive lineup of LEONA™ polyamide resin grades that feature a variety of blends with fillers and other additives.

The core lineup of LEONA™ PA66 resins offers an extensive range of options tailored to specific needs: from standard formulations to glass-fiber (GF) reinforced, low-warp and low-abrasion, impact-resistant, high-viscosity and fatigue-resistant, friction-friendly, heat-resistant, flame-retardant options, and more.

In addition to our comprehensive PA66 offerings, we also provide specialized blends like PA66/6I, which incorporates semi-aromatic polyamide 6I, as well as 66+6I polymer alloys. For environmentally friendly or specialized solutions, we offer grades derived from low-water absorption PA612 and plant-based PA610, which also features low water absorption.

LEONA™ has a wide range of uses with excellent quality to fit your business needs such as materials for:

CHOOSE APNA FOR YOUR PLASTIC NEEDS

Interested in learning more about how LEONA™ can benefit your business? Contact our team of experts today for a personalized consultation and product recommendations.

Your success is our priority, and we are committed to delivering the best PA66 solutions on the market. Choose LEONA™ for a material you can trust to perform.

Contact

LEONA™ SN Key Features

LEONA™ SN is the result of Asahi Kasei's relentless pursuit of innovation. This revolutionary series utilizes non-halogen and red phosphorus free flame retardant, making it an eco-friendly and safe choice for your applications.

This series excels by achieving UL-94 V-0 and compliance with CTI 600V, the highest level of flame resistance for plastic components.

The exclusive features and benefits that LEONA™ SN has to offer include:

Exceptional Heat Resistance

Count on LEONA™ SN to maintain strength and stiffness even under wet conditions, ensuring reliable performance in challenging environments.

Enhanced Processability

Experience reduced mold deposit and metal corrosion, streamlining your production process and improving productivity.

Retained Physical Properties

Enjoy consistently reliable performance, even in conditioned states.

Impressive Surface Appearance

Elevate your products with a visually appealing finish.

Excellent Flammability Performance

In combination with flammable and electrical performance. UL 94 V 0, CTI 600V: Rest assured with top-tier flame retardancy and electrical performance.

Enhanced Productivity

Optimize your manufacturing process with reduced mold deposit compared to conventional alternatives.

Laser Marking Excellence

With impressive laser printability, LEONA™ SN empowers you with clearer laser marking on glossy surfaces, bringing your laser marking capabilities to new heights with wide range of process conditions.

Embrace the Future of Flame Retardants

LEONA™ SN is the result of Asahi Kasei's relentless pursuit of innovation. This revolutionary series utilizes non-halogen and red phosphorus free flame retardant, making it an eco-friendly and safe choice for your applications.

This series excels by achieving UL-94 V-0 and compliance with CTI 600V, the highest level of flame resistance for plastic components.

The exclusive features and benefits that LEONA™ SN has to offer include:

Exceptional Heat Resistance

Count on LEONA™ SN to maintain strength and stiffness even under wet conditions, ensuring reliable performance in challenging environments.

Enhanced Processability

Experience reduced mold deposit and metal corrosion, streamlining your production process and improving productivity.

Retained Physical Properties

Enjoy consistently reliable performance, even in conditioned states.

Impressive Surface Appearance

Elevate your products with a visually appealing finish.

Enhanced Productivity

Optimize your manufacturing process with reduced mold deposit compared to conventional alternatives.

Laser Marking Excellence

With impressive laser printability, LEONA™ SN empowers you with clearer laser marking on glossy surfaces, bringing your laser marking capabilities to new heights with wide range of process conditions.

Excellent Flammability Performance

In combination with flammable and electrical performance. UL 94 V 0, CTI 600V: Rest assured with top-tier flame retardancy and electrical performance.

LEONA™ SN in Action

The LEONA™ SN series introduces an innovative approach by employing non-halogen and non-red phosphorus flame retardant technologies. This series excels by achieving UL-94 V-0 and compliance with CTI 600V, the highest level of flame resistance for plastic components.

LEONA™ SN in Action

The LEONA™ SN series introduces an innovative approach by employing non-halogen and non-red phosphorus flame retardant technologies. This series excels by achieving UL-94 V-0 and compliance with CTI 600V, the highest level of flame resistance for plastic components.

LEONA™ SN – Your Ultimate Solution

Learn More

Download the LEONA™ SN Handbook

LEONA SN PDF Download

TALK WITH OUR EXPERTS TODAY

Asahi Kasei's LEONA™ SN series not only meets the demand for sustainable and safe materials but also delivers unparalleled performance in the automotive and E&E sectors.

Talk to our experts today to discover how Leona™ SN can elevate your projects and take your applications to the next level of excellence. Let us create a safer, greener, and more efficient world together.

Contact

LEONA™ SG Key Features

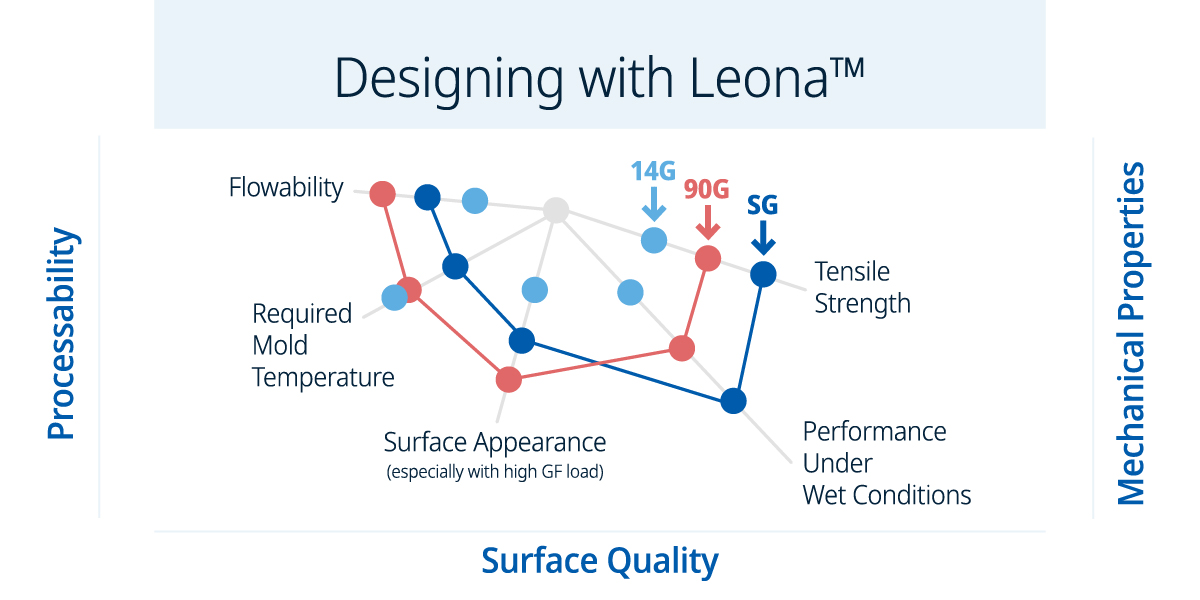

As the newest member of the LEONA™ family, the LEONA™ SG grades are the epitome of excellence, combining outstanding processability, superior strength, stiffness, dimensional stability, and low water absorption. They come with additional features that elevate them as the ideal replacements for metal parts, all while reducing weight.

Lower Water Absorption

Reduced water absorption ensures the material’s performance over time.

Glossy Appearance

Achieve premium aesthetics with LEONA™ SG's excellent surface appearance.

Higher Flowability & Easy Processing

Experience ease in manufacturing processes with LEONA™ SG's higher flowability.

Better Dimensional Stability

Keep your parts in shape and form with LEONA™ SG's superior dimensional stability, ensuring consistency and reliability.

Superior Strength, Stiffness, & Impact Resistance

Embrace robust and high-performing solutions with LEONA™ SG.

Higher Long-Term Creep Resistance

Count on LEONA™ SG to maintain its integrity even under prolonged stress, ensuring long-lasting performance.

Low Odor, VOC, & Fogging

The LEONA™ SG series can be used for automobile interiors due to low odor, VOC, and fogging applications. For example, it meets the VW standards (PV3900, PV3015, and PV3341)

LEONA™ SG Key Features

As the newest member of the LEONA™ family, the LEONA™ SG grades are the epitome of excellence, combining outstanding processability, superior strength, stiffness, dimensional stability, and low water absorption. They come with additional features that elevate them as the ideal replacements for metal parts, all while reducing weight.

Lower Water Absorption

Reduced water absorption ensures the material’s performance over time.

Glossy Appearance

Achieve premium aesthetics with LEONA™ SG's excellent surface appearance.

Higher Flowability & Easy Processing

Experience ease in manufacturing processes with LEONA™ SG's higher flowability.

Better Dimensional Stability

Keep your parts in shape and form with LEONA™ SG's superior dimensional stability, ensuring consistency and reliability.

Superior Strength, Stiffness, & Impact Resistance

Embrace robust and high-performing solutions with LEONA™ SG.

Higher Long-Term Creep Resistance

Count on LEONA™ SG to maintain its integrity even under prolonged stress, ensuring long-lasting performance.

Low Odor, VOC, & Fogging

The LEONA™ SG series can be used for automobile interiors due to low odor, VOC, and fogging applications. For example, it meets the VW standards (PV3900, PV3015, and PV3341)

Advantages of LEONA™ SG

The LEONA™ SG-grades combine metal-like mechanical performance, impeccable surface quality, and remarkable cost-effectiveness, making them the ultimate choice for your projects.

LEONA™ SG’s Grades

LEONA™ SG’s Grades

SPEAK TO OUR EXPERTS TODAY

Are you ready to embrace the future of metal replacement? Contact our experts today to learn more about LEONA™ SG and how it can revolutionize your projects.